Cleanroom Qualification & Environmental Validation Services

Ensure the operational integrity and regulatory compliance of your controlled environments with our comprehensive qualification services. We deliver rigorous, data-driven validation tailored to ISO 14644 standards and GMP guidelines. Our technical scope encompasses precise non-viable particle measurements to verify cleanliness classes, alongside extensive HVAC performance testing, including airflow visualization, filter integrity, and pressure differential analysis.

Beyond physical parameters, we specialize in biological safety, offering viable microbial monitoring and certification for Biosafety Cabinets (BSCs) and laminar flow benches. By providing traceable, audit-ready documentation and detailed technical reporting, we confirm that your facility maintains the strict environmental conditions required for product quality and personnel safety. Rely on our expertise to validate your infrastructure against the most stringent industry benchmarks.

Airflow Visualisation & Velocity Verification

Airflow visualization (smoke Studies)

Advanced airflow visualization techniques (smoke studies) map airflow patterns in real time, verify unidirectional flow characteristics, and pinpoint turbulent zones that could compromise contamination control. By clearly showing how air actually moves through the space, these studies help confirm that cleanroom designs perform as intended, support regulatory compliance, and guide targeted improvements to reduce contamination risk.

Velocity Mapping

Cleanroom internal air speed qualification in critical areas to verify effective product contamination control, ensure consistent airflow patterns, and confirm that cleanroom conditions meet required regulatory and quality standards. Velocity mapping is performed across a matrix of multiple measurement locations within the cleanroom to identify any variations in airflow and to ensure uniform conditions throughout the critical areas.

Computational Fluid Dynamics

With computational fluid dynamics, mathematical modeling, and multiphysics simulation, we can accurately predict airflow behavior, temperature effects, particle movement, and other critical factors. By creating a virtual model of your system before it is built, we can identify potential issues early and optimize the design in advance. This proactive approach helps prevent costly mistakes, especially in situations where changes are difficult or impossible after installation. Ultimately, it reduces risk, saves time and money, and leads to a more reliable, efficient system.

Recovery Testing

Confirms how quickly your cleanrooms return to required cleanliness levels after a contamination event, proving the system performs effectively in real operating conditions and giving you confidence that you can safely resume operations, minimise downtime, maintain product quality and regulatory compliance, and optimise HVAC performance to better control energy consumption and costs

HEPA tests

HEPA tests check that your High Efficiency Particulate Air filters are correctly installed and effectively removing particles from the air. They are carried out in cleanrooms to ensure the airflow remains clean and controlled, protecting your products, processes, and compliance with relevant industry standards. Typical tests include leak testing and efficiency checks, which help you identify issues early, reduce contamination risks, and maintain consistent, reliable cleanroom performance over time.

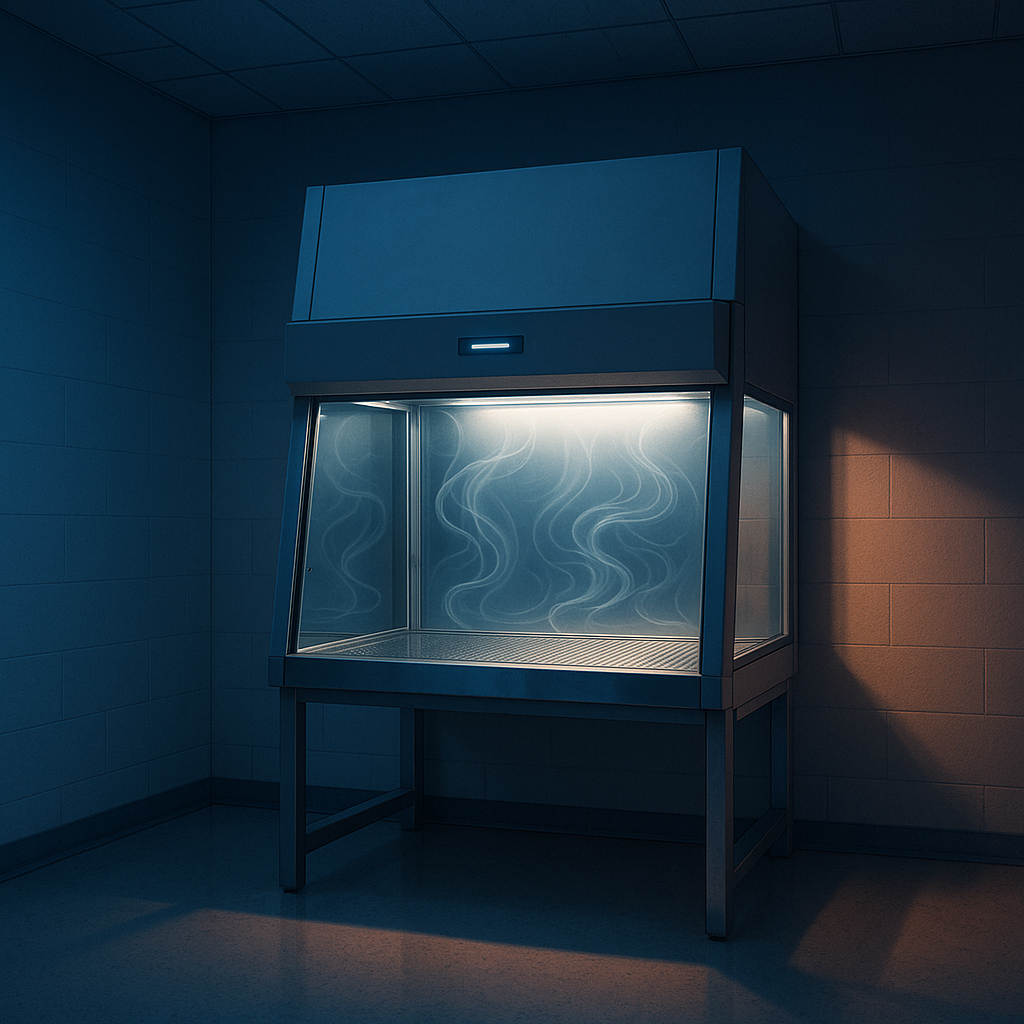

Biosafety cabinet, LAF, Fumehood testing

Our comprehensive testing services for biosafety cabinets, fume hoods, laminar airflow benches and related containment systems ensure they perform safely and in line with international standards. We verify face and downflow velocity profiles to confirm effective containment, and conduct HEPA filter integrity testing to detect any leaks or performance issues.

As part of our qualification process, we perform full Installation Qualification (IQ) and Operational Qualification (OQ) to document that each unit is correctly installed and operating within specified parameters. For fume hoods and containment devices, we carry out KI‑Discus tests to assess operator protection and capture efficiency. Where required, we also perform microbial challenge tests to validate product and personnel protection in biosafety cabinets and clean air devices.

All results are documented in detailed, audit‑ready reports, giving you confidence that your critical containment equipment is safe, compliant and optimised for reliable daily use.

Environmental Monitoring systems and building management systems

Building Management Systems (BMS) and Environmental Monitoring Systems (EMS) provide continuous oversight of your cleanroom by tracking critical parameters such as temperature, humidity, pressure, and particle levels in real time. We help you design and configure system parameters, and offer proactive services to monitor both individual instruments and overall system performance, enabling early issue detection, reduced downtime, and sustained compliance with your process and regulatory requirements.